Yantai XT Machinery Manufacturing Co., Ltd.

Yantai XT Machinery Manufacturing Co., Ltd is an integrated high-tech industrial company involved with

design, manufacture and export the food machinery. We have designed

and developed advanced complete sets of food machinery used to

process nuts, beans, peas, peanut butter, snack food and so on.

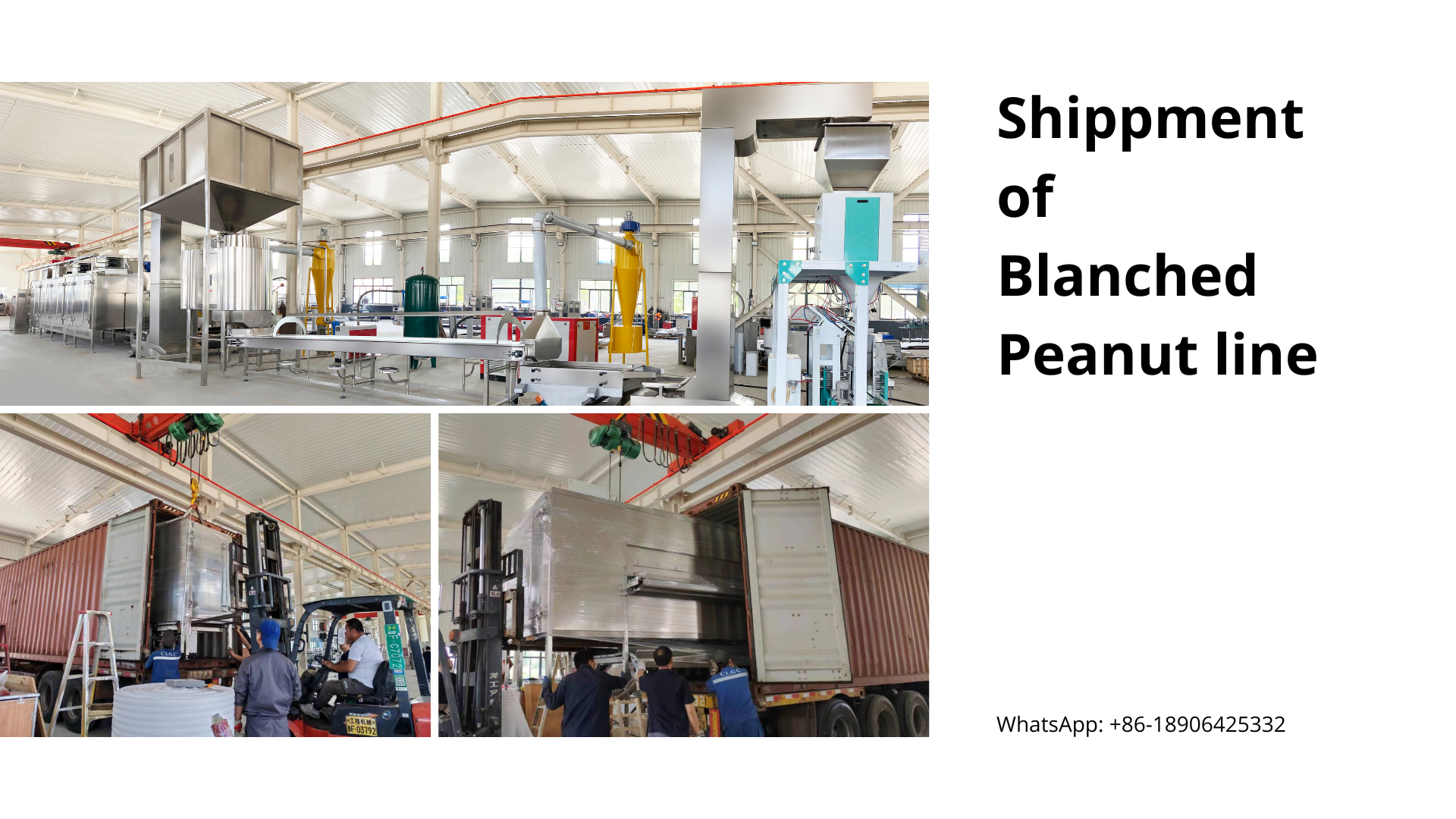

Main products include Nut Peeling Machines, Frying Machines, Nuts Roasting Machines, Peanut Shelling Machine , Coating Machines, Butter Making Machines and kinds of Production Lines, such as Salted Peanut Production Line, Blanched Peanut Production Line ,Fried Peanut and Horse Bean Production Line, Coated Peanut and Cashew Production Line and Nut Butter Production Line, etc.

Our company has professional engineering and technical personnel,

and always creates environmentally friendly, green and

energy-saving high-tech products, and creates reliable brand

machinery for our customers. Besides, we appreciate to customize

the food machinery according to the special design proposal and to

make sure of the maximum benefits to our clients.

Our machines are exported to USA, UK, Spain, Ukraine, Lithuania ,Greece, Turkey, Japan, S.

Korea, Australia, Argentina, Brazil, Colombia, Russia, India,

Pakistan, Bangladesh, Algeria, South Africa, Zimbabwe, Tanzania,

etc.