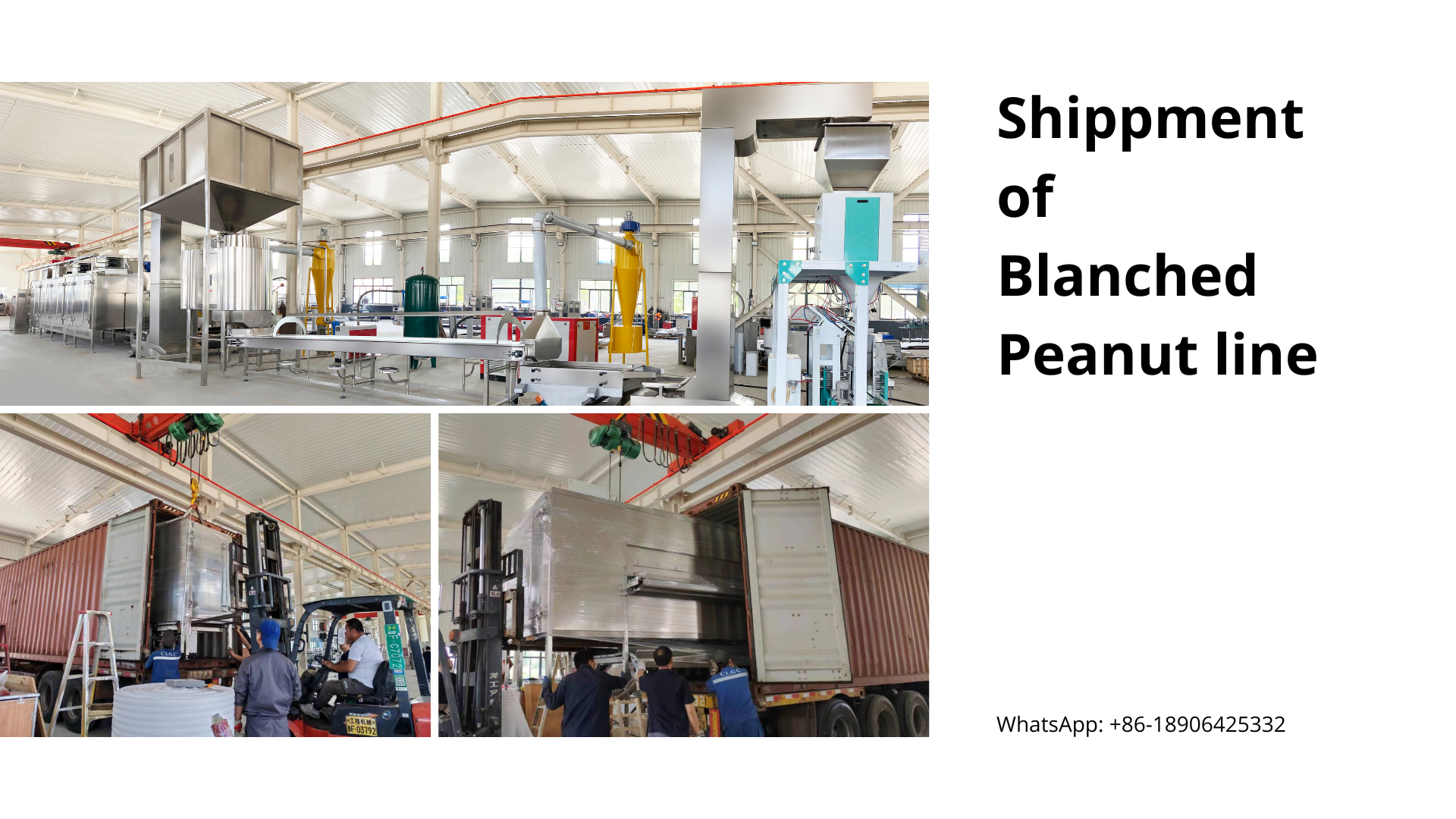

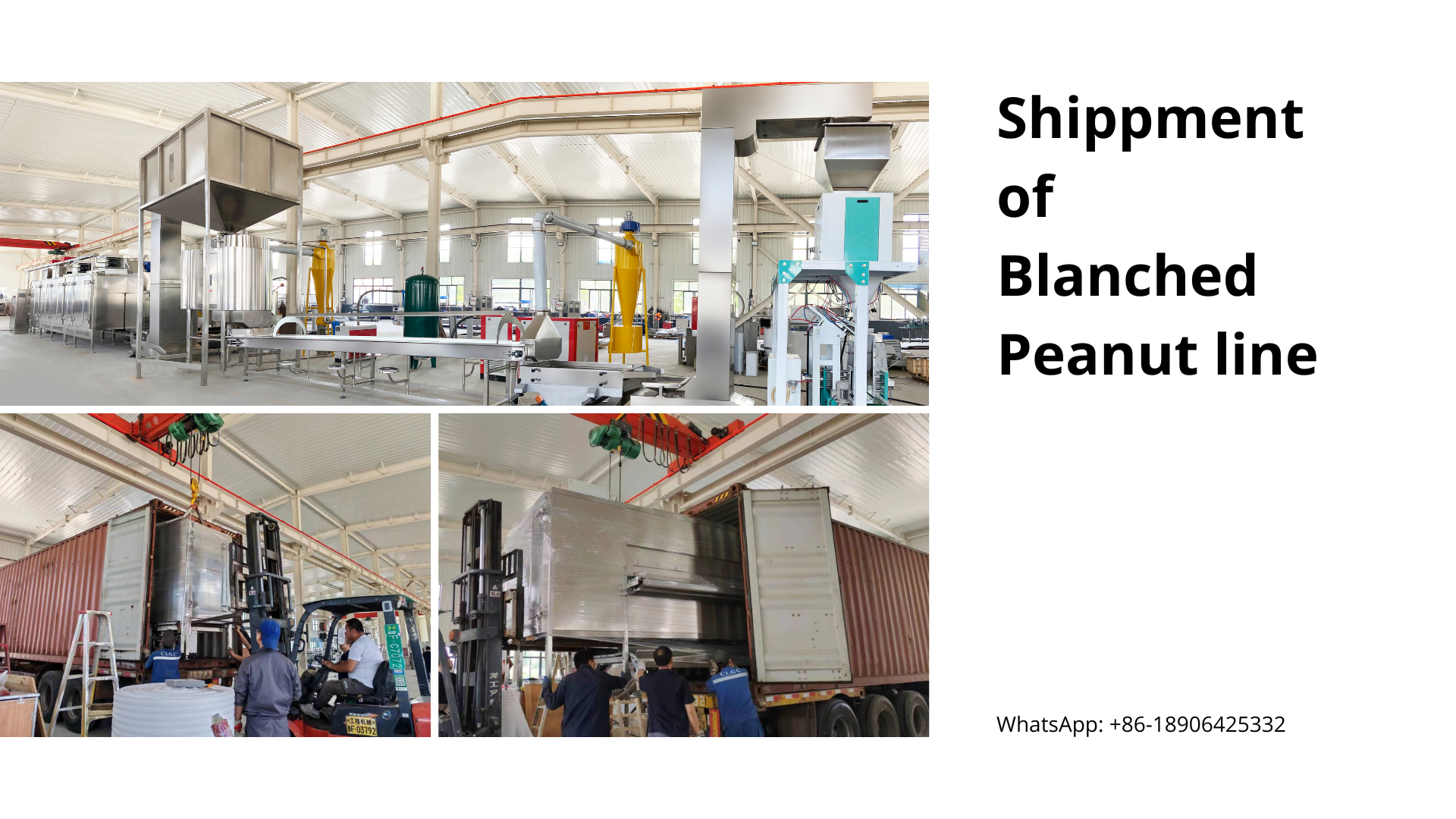

Advanced Temperature Control Peanut Roasting Blanching Line

Blanched Peanut Processing Plant

Advanced Temperature Control Peanut Roasting Blanching Line

Blanched Peanut Processing Plant is mainly used to process blanched peanut hazelhut. Main equipment

is composed of continuous belt type Roaster aslo,air peanut

blanching machine,colorsorter, packing machine .etc. compared with

the traditional production line,this line mainly uses air peanut

blanching machine instead of sand roller blanching. Air Peanut

Blanching Machine uses high-pressure air to remove peanut red skin

and maintain the original color of the peanut without damage to the

surface.

Peanut Roasting Blanching Line Blanched Peanut Processing Plant

1. Peanut Roasting Machine

Function: The Peanut Roasting Machine is one of the core equipment of the

peanut roasting and blanching production line, which is mainly used

for uniform roasting of peanuts. Through precise temperature

control and hot air circulation system, it ensures that the peanuts

are evenly heated during the roasting process to achieve the ideal

roasting effect.

Features: The peanut roasting machine adopts advanced temperature control

technology, which can adjust the roasting temperature and time

according to different varieties of peanuts to ensure the

consistent roasting quality of each batch of peanuts. In addition,

the internal design of the oven is reasonable and easy to clean and

maintain.

Advantages: The Peanut Roasting Machine not only improves the roasting

efficiency of peanuts, but also ensures that the taste and

nutrients of peanuts are retained to the greatest extent. Its

energy-saving design also reduces production costs and is suitable

for large-scale production needs.

2. Peanut Air Blanching machine

Function: The Peanut Air blanching machine is used to remove the red skin on

the surface of peanuts, and achieves efficient peeling through the

combination of high-speed airflow and mechanical friction.

Features: The equipment adopts a dust-free design to avoid dust pollution

generated in traditional peeling methods. At the same time, the

adjustment device of the blanching machine can be adjusted

according to the size and variety of peanuts to ensure the best

peeling effect.

Advantages: The air blanching machine not only has high peeling efficiency,

but also has little damage to peanuts, maintaining the integrity

and appearance of peanuts. Its automated operation reduces manual

intervention and improves the overall efficiency of the production

line.

3. Picking belt

Function: The picking belt is used to screen and sort the peeled peanuts and

remove unqualified peanuts and impurities.

Features: The picking belt uses high-precision sensors and image recognition

technology to quickly and accurately identify unqualified peanuts.

At the same time, the speed of the picking belt is adjustable to

meet different production needs.

Advantages: The picking belt greatly improves the screening efficiency and

quality of peanuts and reduces the labor intensity of manual

screening. Its intelligent design ensures the accuracy and

consistency of the screening process and improves the quality of

the final product.

4. Vacuum weighing and packaging machine

Function: The vacuum weighing and packaging machine is used to weigh and

vacuum pack the screened peanuts to ensure the freshness and shelf

life of the peanuts.

Features: The equipment integrates weighing, packaging and vacuum sealing,

is easy to operate and has a high degree of automation. The

packaging material can be selected according to customer needs to

ensure the sealing and aesthetics of the packaging.

Advantages: The vacuum weighing packaging machine not only improves the

packaging efficiency, but also extends the shelf life of peanuts

through vacuum treatment, maintaining the taste and nutritional

content of peanuts. Its precise weighing system ensures the

consistent weight of each package of peanuts, enhancing the market

competitiveness of the product.

Summary

The entire Peanut Roasting Blanching Line Blanched Peanut Processing Plant integrates roasting, blanching, picking and packaging, with the

advantages of high efficiency, automation, energy saving and

environmental protection. Through advanced technology and

equipment, the quality and taste of peanuts are ensured, meeting

the needs of large-scale production, and is an ideal choice for the

peanut processing industry.